10 Proven Techniques for Chamfering Metal Pipes

Chamfering metal pipes is an important process in many industries because it makes the pipe ends smooth and beveled for easy joining and optimum performance. Be it as a plumber, constructor, or manufacturer, knowing how to chamfer metal pipes correctly will help improve the quality and efficiency of your projects. We will cover different techniques, tools, and best practices for chamfering metal pipes so that you can execute the process precisely and reliably.

What is Chamfering?

Chamfering is a procedure for beveling the end of a material, usually at an angle of 45 degrees. The technique is applied to remove sharp edges and burrs from a workpiece so that it can be handled safely and easily joined with other components. In the case of metal pipes, the pipe ends are chamfered to ensure they are smooth and prepared appropriate for either welding or fitting.

Why Chamfer Metal Pipes?

Benefits

- Better Fit: Chamfered edges provide for a tighter, more secure fit of the pipes at the point of connection, thus ensuring the integrity of the joint.

- Easier Welding: A chamfered edge sets up the pipe ends for welding by creating an angle that allows the welding material to be properly seated.

- Safety: Eliminate sharp edges to minimize the potential for cuts, gashes, and other injuries during handling or installation.

Use Cases

- Plumbing: Pipes fully fit together to avoid leaking and improve durability.

- Construction: Prepares pipes for structural applications, working under stress and pressure.

- Manufacturing: Ensures that assembled products have higher quality and precision.

Chamfering Metal Pipes Tools

Manual Tools

- Hand Files: Small-scale chamfering and deburring tasks.

- Deburring Tools: Designed to remove burrs and create smooth edges on metal pipes.

- Sanding Methods: The Chamfer edges can be smoothened out by rubbing with sandpaper or sanding blocks.

Power Tools

- Angle Grinders: With grinding disc attachments for beveling the edges of metal pipes

- Electric Chamfering Machines: For constant and sharp chamfering in pipes of all sizes

- Pneumatic Tools: These work using compressed air to drive the chamfering activity at very high speeds

CNC Machines

- CNC Machines: Computer Numerically Controlled machines create precision, rapid automated chamfering, suitable for big industrial applications.

Manual Methods of Chamfering

Hand Files

Use a hand file and bevel the edge of the metal pipe. Go back and forth with the filing tool in a prolonged uniform angle. Works for small pipes and minor tasks related to chamfering.

Deburring Tools

Deburring tools have been specially designed for the removal of burrs and the smoothing of edges; they come in different shapes and sizes, thus working well in different diameters of pipes.

Sanding

After chamfering with sandpaper by a sanding block looking out for the removal of edges so that it becomes smooth without any rough spots.

Power Tool for Chamfering

Angle Grinders

An angle grinder is a useful device for producing a chamfer in a steel pipe. With a grinding disc, lightly move the grinder along the edge of the pipe, ensuring proper chamfering.

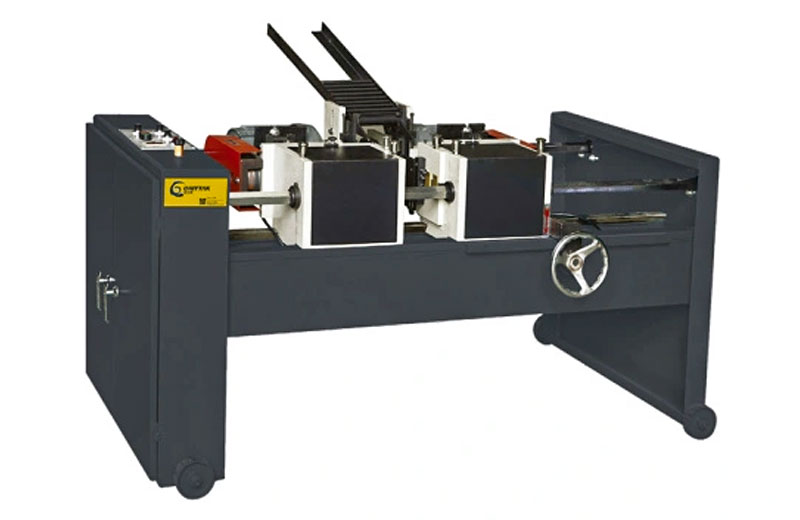

Electric Chamfering Machines

These electric machines allow one to get consistent and accurate results. These machines, owing to the versatility of the different sizes and materials of the pipe handling capacity, can undertake work both on large and small projects.

Safety Precautions

- Always wear protective gear that includes safety glasses, gloves, and hearing protection.

- Keep the working area clean and clear of any obstruction.

- Always work with power tools per the manufacturer's instructions to ensure safe usage.

CNC Chamfering for Metal Pipes

Advantages

- Accuracy: The machines provide an accurate chamfering, guaranteeing homogeneous edges.

- Automation: The time consumed by manual labor is decreased; a maximum production pace is assured.

- Consistency: The results obtained will be alike across large runs in production.

Programming

A more advanced variant of beveling is carried out with the help of CNC machines that are programmed with the help of particular software, performing the chamfering process by reading the dimension and angle requirements fed into the device by operators. The machines then proceed to execute this process automatically.

Industrial Applications

Prospective applications of CNC chamfering can be found in many industries where high accuracy and large-scale production are needed, which also includes automotive manufacturing and aerospace engineering.

Best Practices for Chamfering Metal Pipes

Preparation

- Clean off pipe ends from any dirt or debris.

- Measure and mark the area to be chamfered. This will give it accuracy.

Method

- The chamfer has to be done in a constant angle so as to form straight edges.

- Use the correct tool according to the material and size of the pipe.

Finishing

- Sand the edges nicely with sandpaper or by using a sanding block.

- Check for any burrs or rough spots, that may have been left on the edges.

Common Problems in Chamfering Metal Pipes

Formation of Burrs

During chamfering, there could be the formation of burrs, which results in rough edges. Remove these with the help of deburring tools.

Uneven Edges

This situation occurs due to inconsistent angles of the chamfering tool. While working on a piece, always hold the tool at a constant angle.

Tool Wear

Due to frequent use, these chamfering tools become ineffective and experience wear. Check and change these frequently so that the work turns out in good quality.

Safety Tips for Chamfering Metal Pipes

- Protective Equipment: Wear safety glasses and gloves, and always use your hearing protection.

- Holding the Work Safe: The pipe must be properly secured before the end is chamfered to prevent pipe movement.

- Maintenance of Machine: Any chamfering machine must have a regular maintenance schedule in place for continued safe operation and its extended life.

Selection of a Suitable Chamfering Technique

Need Assessment

Consider the volume of pipes to be chamfered and the required precision. Manual methods can work with modest projects, while power tools and CNC machines represent a larger operation.

Material Considerations

Not all metals can be joined in the same way. Use the correct method depending on what the pipe's material is.

Project Scale

Large project: invest in an automated tool or a CNC machine to gain efficiency and consistency.

Innovations in Chamfering Technology

Latest Tools

Advanced Deburring Tools: New designs offer improved control and precision

Automated Chamfering Machines: Improved models provide faster and more accurate results

Advanced Techniques

- Laser Chamfering: This process makes use of laser technology to come up with precise bevels, all this without physical contact.

- Robotic Chamfering: The process can be automated by using robots fitted with a chamfering tool in high-volume production environments.

Future Trends

- Smart Chamfering Machines: The machines would be integrated with smart technology for real-time monitoring and adjustment.

- Eco-Friendly Solutions: Development of energy-efficient and environment-friendly techniques of chamfering.

Ecological Effects of Chamfering

Waste Management

Proper waste management involves handling the disposal of metal shavings and other particles resulting from such processes as chamfering.

Eco-Friendly Practices

Choose energy-efficient machines and adopt processes that minimize environmental impact.

Energy Efficiency

Use such tools and machines for chamfering, which will decrease the consumption of power without affecting its performance.

Training and Certification

Training Programs

Always attend the training programs given by the manufacturer or by the organisations dealing with it to understand the correct methodology of chamfering and handling the tool .

Certifications

Obtain certifications to be qualified in the chamfering process and safety measurement.

Best Practices

Ensure the following of industry best practices to obtain quality output and safe operations.

Cost Analysis of Chamfering Metal Pipes

Equipment Costs

Chamfering tools and machines—imeline investment considerations; high-end equipment can provide better performance and service life.

Operational Expenses

More on power, maintenance, and replacement parts.

Return on Investment

Calculate a potential return on investment through increased efficiency, reduced labor cost, and improved product quality.

Conclusion

The process of chamfering of a metal pipe is required for the creation of correct, smooth, and safe edges that increase the final quality of the products and their durability. It's quite possible to achieve great results by learning a number of techniques of chamfering by different tools and following the best practices. Stay updated on new innovations and tendencies to keep in pace with your competitors.