The Ultimate Guide to Choosing and Using a Pipe Chamfering Machine

It is in the context of industrial manufacturing that precision and efficiency are considered a necessity. Probably one of the single most important instruments to influence these qualities is the pipe chamfering machine. Businesses working in plumbing, metal fabrication, and other similar piping industries should be able to gain invaluable operational efficiency and improved product quality once the techniques for choosing and using an effective pipe chamfering machine are learned.

What is a Pipe Chamfering Machine?

A pipe chamfering machine is a device designed to bevel or chamfer a pipe end. This is very important in making pipes easily fit together, hence easily weldable and making a structure much stronger. It simply refers to the removal of burrs from the edge of the pipe, which involves cutting or grinding at an angle, mostly 45 degrees, to prepare it for joining.

Types of Pipe Chamfering Machines

Manual Chamfering Machines

Manual machines are explicitly made to be operated directly by a human and are more beneficial in small-scale or low-volume tasks of chamfering. They are normally more pocket-friendly but they demand so much more physical effort and precision from the operator.

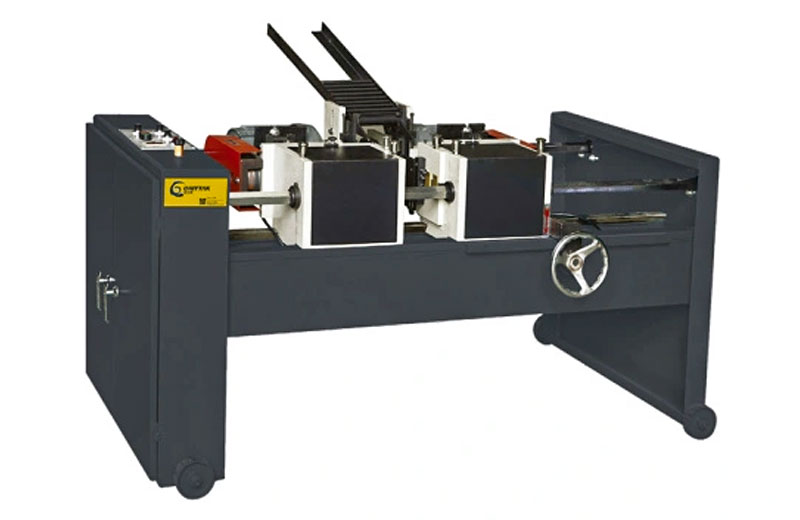

Automatic Chamfering Machines

Automatic machines produce in a large volume production environment—much more consistency and efficiency, hence less manual intervention, reduced errors.

Pneumatic Chamfering Machines

Pneumatic chamfering machines, however, benefit from compressed air that drives the chamfering operation. Inching slowly with unrivaled speed, they have a place in industries that depend largely on speed.

Electric Chamfering Machines

Electric chamfering machines are all-rounded machines capable of handling a diversified range of materials used to make pipes and a myriad of sizes. The reliability and ease of use give them wide popularity in industrial and workshop environments alike.

CNC Chamfering Machines

High accuracy and automation are realized through CNC chamfering machines. Such machines are programmed to produce complicated chamfering tasks with very minimal human input. Therefore, in case you need a high-volume manufacturing operation, they will be just perfect.

How Pipe Chamfering Machines Work

Pipe chamfering machines work by clamping the pipe securely in place and using a rotating cutting tool to execute a desired bevel. Some of the main components include clamping mechanisms, cutting tools, and power sources. Primary activities involved in the process of chamfering are as follows:

- Securement of Pipe: The pipe that has to be chamfered is firmly gripped to avoid its movements during the process.

- Rotating the Cutting Tool: A cutting tool, normally a carbide or high-velocity steel blade, is rotated at intense speeds.

- Creating the Chamfer: Contact the rotating tool with the pipe end. This will cut away material to create a chamfer.

- Finishing: Smooth the chamfered edge to remove any burrs or rough edges from it.

Advantages of Pipe Chamfering Machines

Accuracy

Pipe chamfering machines offer accurate and constant results to ensure that each end of every pipe is beveled uniformly. This accuracy is quite critical in making strong and long-lasting joints.

Efficiency

Automating the process of chamfering drastically saves time and manpower, thereby increasing overall production efficiency.

Safety

These machines decrease the possible risk of operator injury from sharp edges or flying metal due to manual methods of chamfering.

Cost-Effectiveness

Review the cost-saving advantages in the long term by way of reducing labor costs with the help of a chamfering machine, and minimize material wastage.

Pipe Chamfering Machines: Areas of Application

As a result of their versatility and efficiency, the machines find application in many different industries. Common applications include:

Plumbing

The beveled edges that are produced are clean, hence the pipes can be easily fitted together to form secure joints.

HVAC

The machines prepare the pipes for seamless integration into heating, ventilation, and air conditioning systems.

Automotive

Chamfering pipes for exhaust systems, hydraulic lines, and other critical components.

Construction

Preparation of pipes intended for structural and infrastructural projects to ensure durability and reliability.

Manufacturing

Assurance that manufactured products that display pipe systems would be of enhanced quality and uniformity in their lookout.

Key Features to Look out for in a Pipe Chamfering Machine

As one chooses a pipe chamfering machine, the following are key features to look out for:

Durability

Do look for machines made out of high-quality materials, sturdily built to undertake continuous work.

Versatility

Choose a machine that deals with a diversity of pipe sizes and materials to suit your needs.

Ease of Use

Opt for a machine with user-friendly controls and clear instructions to reduce time for training and limiting errors.

Maintenance

Look into the ease of maintenance and acquired replacement parts for its long-term operability.

Selecting the Right Pipe Chamfering Machine

The right pipe chamfering machine will have to be chosen based on your specific needs and budget. Important considerations include:

Needs Assessment

Volume and types of pipes that will be chamfered, determined by how many and what kinds of pipes one will chamfer.

Budget

Balance the up-front costs against long-term benefits and possible cost savings with a machine.

Machine Specifications

Compare specifications of different machines like the source of power, speed, and precision to find the best fit.

Brand Reputation

Research the manufacturer's reputation and read reviews to ensure that your investment is a reliable and high-end product.

Top Brands for Pipe Chamfering Machines

Some of the leading manufacturers in the area of pipe chamfering machines are mentioned below:

Chittak: They provide a full range of pipe chamfering machines to help you chamfer or bevel the ends of steel, carbon steel, iron, copper, aluminum and other metal pipes.

Ridgid: Known for tools that stand for durability and reliability, Ridgid offers a wide array of sturdy chamfering machines to help give coverage to every possible usage.

Baileigh Industrial: It represents a highly efficient line of machines designed for use in industrial processes. It focuses on precision and efficiency.

DWT GmbH: Specialized equipment for the preparation of pipes; it leads in chamfering machines used by all workshops involved in welding and construction.

Setting Up a Pipe Chamfering Machine

Setup is very crucial to ensure you have peak performance as well as safety. This section will lead you through setting up your pipe chamfering machine.

Installation Process

Mount the machine on a stable surface and anchor it. Connect the power source and, if necessary, any air supply for pneumatic models.

Initial Calibration

Calibrate the machine according to the manufacturer's instructions to achieve an accurate chamfer.

Safety Precautions

Go through all the safety guidelines given by the manufacturer on how to avoid accidents and injuries.

Safe Operation of the Pipe Chamfering Machine

There are some safety considerations in the operation of pipe chamfering machines. The following guides will ensure safe operation:

Safety Precautions

- Protective gear such as safety glasses and gloves shall be worn at all times.

- Work area should always be kept clean and obstruction-free.

- The machine has to be used according to the recommendations by the manufacturer.

Common Risks

Monitor for common hazards: sharp edges, flying debris, potential machine malfunction.

Protective Gear

Ensure protective gear is worn by all operators to avoid injuries.

Maintaining Your Pipe Chamfering Machine

Regular maintenance is required for your pipe chamfering machine to function effectively. Here are some maintenance tips for the machine:

Regular Checks

The parts of the machine have to be regularly checked against wear or damage.

Cleaning

The machine should be kept clean, with all shavings and other material deposits evacuating from the work area after every use.

Part Replacement

Replace worn or damaged parts in the shortest time to avoid further damage and to retain efficiency.

Professional Servicing

The machine must be professionally serviced regularly in order for it to be kept in good condition.

Common Problems and Troubleshooting Tips

Machine Jamming

In case of jamming, check for blockages or material accumulation and ensure cleanliness before continuing to use.

Poor Chamfer Quality

Check if the cutting tool is not blunt and also check that it is properly aligned. If need be, adjust the machine setting.

Power Issues

The power source should be checked with its connection to ensure the machine has relatively sufficient power.

Overheating

Let the machine cool a bit at recurrent intervals. This avoids overheating of the machine, which when it occurs may result in damage.

Pipe Chamfering Technology Innovations

Innovations on pipe chamfering technology have been on enhancing efficiency, precision and user-friendliness. Some of the key developments include:

New Developments

State-of-the-art cutting gadgets and automation features improve the chamfering process.

Automation

Increased use of automation to reduce manual labor and increase consistency.

Smart Features

Increased integration of smart features like digital controls and monitoring systems that would improve their performance.

Environmental Impact of Pipe Chamfering Machines

It is vital for one to understand the environmental impact of those machines before one embarks on an adoption spree for pipe chamfering machines that ensure eco-friendliness.

Energy Consumption

Opt for energy-efficient models in a bid to bring down power consumption and subsequently lower operation costs.

Waste Management

Ensure proper waste management that shall reduce its impact on the environment once the materials involved are disposed of.

Eco-Friendly Techniques

Use machines and processes that create minimal wastes, with low carbon footprints.

Trainings in Pipe Chamfering Machine Use

Proper trainings will make sure that the pipe chamfering machines are used safely and effectively. Some trainings to consider are as follows:

Training in Programs

Enroll operators for training under the manufacturers' or trade associations' programs.

Certification

Get certifications that approve one to operate a chamfering machine.

Best Practice

Abide by the best practices in the industry to achieve optimal performance and safety.

Cost Analysis of the Pipe Chamfering Machine

A cost analysis of the pipe chamfering machine gives insights into the financial burden that an investment in the machine comes with.

Upfront Cost

A look at the upfront cost of the purchase price of the tool and any other complementary accessories

Operational Costs

costs of power consumption, maintenance, and parts replacement

ROI

Return on investment from potential increased efficiency and decrease of labor cost can be now calculated.

Comparison of Pipe Chamfering Machines with Alternative Methods

Understanding how pipe chamfering machines compare with other methods.

Manual Chamfering

Manual chamfering is time-consuming. It is not as accurate as machine chamfering.

Grinding

Grinding might be effective, but it cannot produce the same precision and consistency as chamfering machines.

Alternative Tools

Look at other tools and methods and decide which one will suit your needs best.

Future Trends in Pipe Chamfering

Be ahead with the knowledge of future trends and market predictions on pipe chamfering machines.

Market Predictions

High-precision and automated solutions in the area of chamfering are expected to be increasingly in demand.

Emerging Technologies

Keep a lookout for new technologies that assist in backing up efficiency and precision in the processes of chamfering.

Industry Demands

Keep watch on the changing industry demands, which will set a different viewpoint regarding the future of the machines for chamfering pipes.

Conclusion

The proper selection of pipe chamfering machines and their correct utilization can increase operational efficiency, enhance product quality, and eventually improve the safety of a workplace. You shall be able to make appropriate choices if you understand the different categories of these machines available in the market and their features, plus the proper maintenance practices that will keep them updated and running at their best. Keep current with new innovations and trends that help in keeping your processes on the leading edge of technology.